Overview

Gene transferring technology is an increasingly noteworthy topic as it relates to the development of novel mRNA-based therapies. Fueled by enhanced genetic tools and improved technologies, the clinical market is set to introduce many more gene therapies in the next decade. Clinical research in this area is uncovering a great deal of potential with mRNA-based therapies, giving rise to the newly coined age of precision medicine.

At the center of mRNA research and development efforts are LNPs (lipid nanoparticles). There are approximately 90 leading vaccine developers in the clinical market share and about 137 mRNA therapeutics active in the preclinical and development stage of the FDA pre-approval process, (76% in preclinical/exploratory and 24% in clinical development).

Examining the Properties of a Lipid Nanoparticle

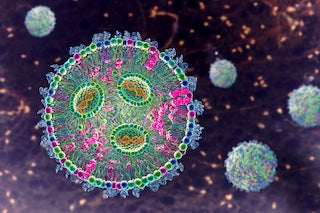

A lipid nanoparticle (LNP) is composed of hundreds of small interfering RNA (siRNA) molecules that are enveloped by ionizable lipids, phospholipids, and cholesterol. These particles make it possible for the DNA to penetrate the cell, making them essential to the mRNA development process.

K2 Scientific is especially interested in how these mRNA-based therapeutics are quite literally changing the climate of cold storage in nearly every clinical environment - (no pun intended). Following a few key assessments from the Covid-19 vaccine rollout, medical refrigeration is going to play an even bigger role in the future of pharmaceutical endeavors.

The Link Between Lipid Nanoparticles (LNPs) and mRNA Therapeutics

Lipid nanoparticles are used to deliver a piece of DNA into a cell. LNPs are referred to as a non-viral gene delivery system. As the genetic therapeutic landscape continues to break new ground, non-viral approaches are gathering momentum. LNPs are a key advancement in the development of many new drug therapies used to treat chronic conditions and diseases.

LNPs were hailed as the unsung hero for COVID-19 vaccines – without them, manufacturing would not have been possible. There were four LNP ingredients used in the COVID-19 vaccine formulary: ionizable lipids (containing positive charges) that bind to the negatively charged backbone of mRNA, pegylated lipids used to achieve greater stabilization, and phospholipids and cholesterol molecules that help contribute towards the complete LNP structure.

LNP development has been a headache, but without this packaging, mRNA vaccines would be nothing. “It is the unsung hero of the whole thing,” says Giuseppe Ciaramella, who was head of infectious diseases at Moderna from 2014 to 2018.

Researchers had trouble finding a delivery vehicle able to penetrate fragile cell membranes. However, LNPs were able to accomplish delivery without compromising the health of the cell or the delicate mRNA strands. Characteristically, LNPs have a small internal aqueous presence making them well-suited for achieving stable cell encapsulation of genetic materials.

The main advantages of LNPs are improved stability, targeting, and delivery efficiency for oligonucleotide active pharmaceutical ingredients (APIs). LNPs also as a sort of protective agent for the API preventing premature degradation. Paired with the low cost of scaling mass production, LNPs gained an attractive value option in the clinical marketplace.

Challenges Associated with Using Lipid Nanoparticles

In truth, there has been a bit of an industry shift relating to using LNPs in routine pharmaceutical formularies. The use of LNPs has been dubbed a cumbersome methodology by many in the scientific community, but they are gaining more traction recently because of stability improvements, and more efficient targeting. Researchers find LNPs work well with complex oligonucleotide-based APIs and offer a predictable avenue towards cell-delivery especially those with complex or multiple payloads.

Drug Synthesis

Synthesizing nanoparticles is a complex process and requires a different sort of formulation expertise compared to traditional fill-finish activities for parenteral products where the API is essentially combined with a mixture of buffer and excipient ingredients. With LNPs, you need a good understanding of exactly how to mix the molecules; flow rates, temperatures, composition, and component ratios are all crucial to influence the formation of the nanoparticles and efficiently encapsulating the API.

Stability

Clinical studies evaluating the stability of LNPs relating to pH, humidity, temperature, and lyophilization reveal a greater understanding of how to safely store these types of compounds. Key evidence supports LNP temperature volatility in addition to a few other important co-factors such as mRNA hydrolysis, degradation-prone sites, and mRNA nucleotide optimization. Optimizing the stability of LNPs is rooted in lyophilization and temperature control creating a surge in demand for medical refrigeration and freezers.

Supply Chain Issues

There are relatively few facilities that possess the equipment and facilities to scale out the forecasted need for lipids nanoparticles, or the special ionizable cationic lipids. To the layperson, LNPs probably seem like something you’d reach for on a shelf or have on hand in a laboratory freezer, but that’s not exactly how it goes. LNPs are at present sort of a made-to-order type of ingredient – at least for the short term. Bringing forth a mass-scale production effort to reality is a continuous challenge for the small number of companies in charge of manufacturing LNPs.

Ionizable cationic lipids are produced synthetically in what can be an incredibly laborious process requiring anywhere from 14 and 20 complex steps to complete production, according to Padma Kodukula, the chief business officer at the genetics medicine company Precision Nanosystems that works on mRNA and lipid nanoparticle technology.

While LNPs are not a new player in the clinical marketplace, they only recently gained FDA approval a few years ago for another unrelated treatment application. Consequently, the expedited demand for nearly 16 billion covid-19 vaccines overloaded the supply chain before it even began. This makes a case for preserving the LNPs that are made and ready for advanced downstream formulations. Enter the viability for long-term preservation practices – are ultra-low freezers the answer?

Best Storage Practices for Liquid Nanoparticles

Freshly preparing LNPs for each experiment is a time-consuming endeavor. For mass scale, such as in the production of mRNA therapeutics, it is beneficial to work towards long-term cold storage solutions. Doing so could save time, and cost, and improve clinical trial consistency.

Long-term solutions for liposome-based drug delivery systems such as LNPs, and cationic liposome complexes (lipoplexes) are a bit tricky. Lipoplexes tend to become highly unstable in solution and form aggregates during long-term storage at room temperature.

What we know about storing LNPs successfully is that:

Clinical studies indicate that when stored under aqueous conditions, medical refrigeration (2°C) kept LNPs the most stable over 150 days. Because the pH of the storage buffer was not found to influence stability, it is suggested that the LNPs be stored under physiologically appropriate conditions (pH 7) for ease of use.

For longer storage periods (over 150 days), it appears that lyophilized conditions or subzero temperature housing yields similar results according to a recent report. The observation study chronicled various components of the liquids involved in the aqueous LNP structure at various temperature settings. Using advanced chromatography, research scientists were able to narrow each component and note changes to their molecular structure, size, and mechanism of action.

The findings support minimal changes in structure or therapeutic efficacy after one year. As of this date, formalized guidance on LNP storage has yet to be expanded upon. There is, however, detailed temperature guidance about each unique mRNA therapeutic active within the clinical space.

Sourcing High Performance, Medical Grade Refrigeration for LNP and mRNA Experiments

Medical refrigerators and lab freezers need to be accurate and reliable. K2 Scientific offers several different medical-grade refrigerators and freezers for hospitals, pharmacies, laboratories, and clinics. Our products are CDC and VFC compliant. Outfitted with various features, such as programmable temperature control and audible and visual alarms, these medical refrigerators and freezers are trusted by industry professionals throughout the country.

K2 Scientific medical refrigerators and lab freezers are available in several different styles to accommodate space and cold storage requirements. Choose from bench-top, upright, and under-counter styles.

K2 High-Performance medical-grade refrigerators and freezers carry a 2-year parts and labor warranty and a 5-year compressor warranty. K2 Value Performance units carry a 2-year full replacement warranty. Warranty details.